What is A Hydraulic Breaker And what is It Used For?

페이지 정보

본문

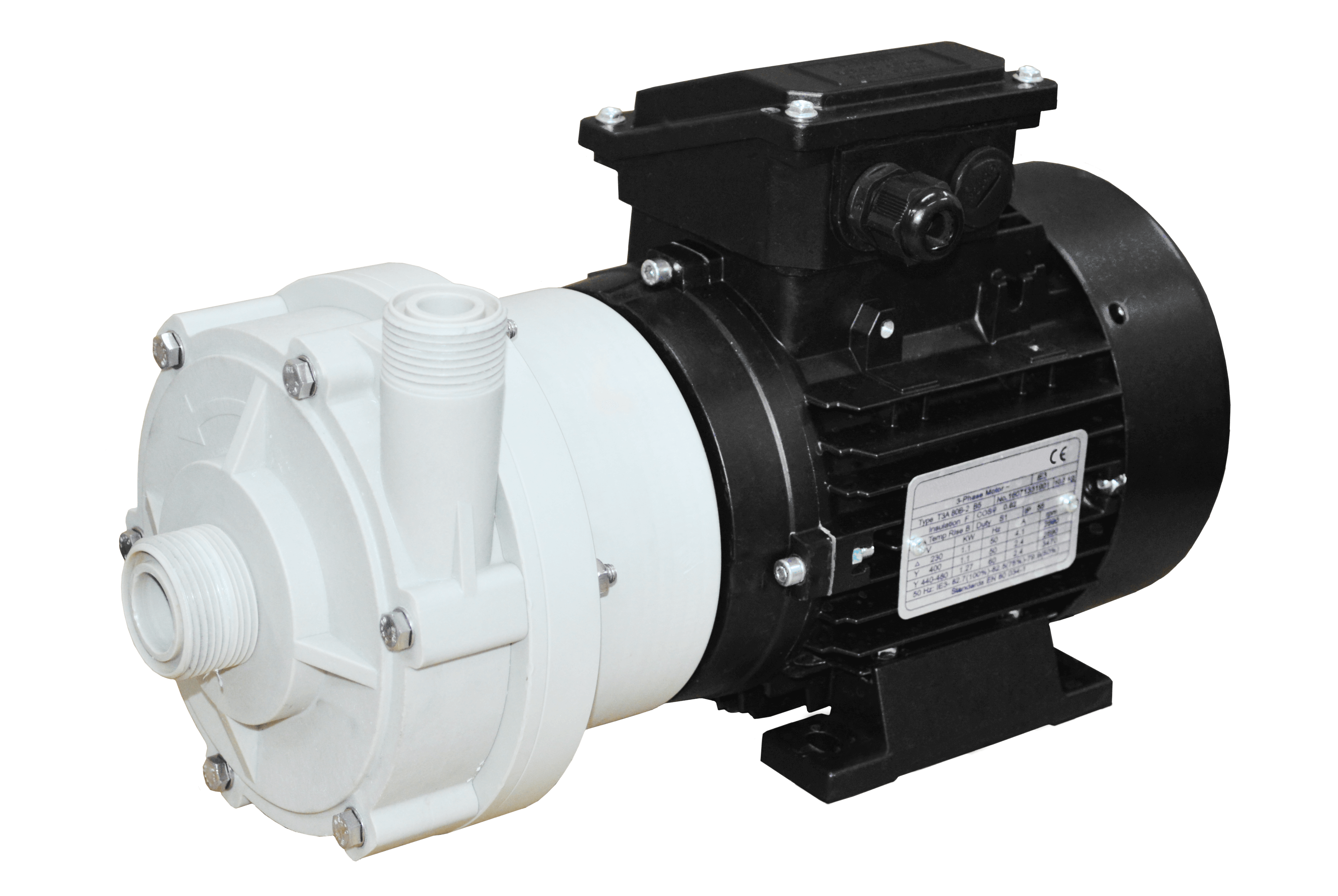

They encompass a hydraulic piston mechanism housed in a durable casing, with a chisel or pointed device at the working end. The hydraulic system then provides the mandatory power to propel the piston and ship repeated blows to the goal surface, successfully breaking it apart. Hydraulic breakers are commonly utilized in demolition tasks to dismantle constructions, including buildings, bridges, roads and pavements. They excel at breaking by concrete, brick and masonry, permitting for efficient removing of unwanted structures and supplies. Whether it's a small-scale renovation venture or a big-scale demolition site, hydraulic breakers provide the necessary force to deal with powerful materials quickly and successfully. Within the quarrying and mining industries, hydraulic breakers are essential for extracting uncooked materials from the earth.

Oil filtration: When adding hydraulic oil to the system, you may filter it via a portable filter to maximise gear productiveness and efficiency. Filter adjustments: To get the most out of your hydraulic fluid, you must change and test your fluid filters frequently. One among the largest risks in hydraulic programs is the event of sizzling spots that could cause the system to overheat. Hydraulic fluid being pushed by pumps and lines causes it to heat up, which is why it’s essential to routinely test the system’s temperature. Equipment has a constructed-in thermometer that operators can watch to make sure it doesn’t rise past a sure threshold recommended by the manufacturer. Nevertheless, a complete system temperature could not determine particular sizzling spots. Clear the excavator after each use to remove any dirt, debris, or mud that will have accumulated. This will assist forestall corrosion and harm to the machine. Comply with the maintenance schedule as advisable by the producer. This will likely embrace oil modifications, filter replacements, and different routine maintenance tasks. In case you experience any issues together with your excavator, it’s important to deal with them promptly to stop additional injury.

This software highlights the versatility of hydraulic breakers and their capacity to handle a wider vary of duties beyond just concrete and rock breaking. Q1: How do I select the fitting measurement hydraulic breaker for my excavator? The suitable breaker dimension hinges on two key factors: the carrying capacity of your excavator and the kind of fabric you’ll be breaking. This machine is driven and managed by the following programs.- The principle hydraulic system provides oil to the cylinders and motors of the machine. The pilot hydraulic system supplies oil to the management circuits. The digital control system controls the output from the engine and the pump. The principle hydraulic system oil is equipped by higher pump (28) and decrease A10VSO pump (29). Pumps (28) and (29) are variable displacement piston pumps. Operators may need to choose from steel platforms ranging in measurement from 1.22 meters to 2.Forty four meters or from four to eight ft. There are a variety of available platform accessories to assist modify the carry for its particular use. Platform equipment might embrace the next gadgets: fluorescent tube caddy, half-top mesh, auxiliary top railing, control field cowl, work lights, welder leads and power tray. Cargotec's Kalmar product vary is frequent in terminals and ports all around the globe. Their Medium and Mild forklift trucks are perfect for superior dealing with since they're versatile, easy to function, easy to maneuver and could be modified so as to suit all your requirements. From repair to upkeep to coaching; Kalmar provides a whole range of companies.

Excavator hydraulic pumps, like every mechanical part, can encounter a number of frequent points over time. Being conscious of those points and figuring out how to handle them promptly is essential for sustaining optimal efficiency and minimizing downtime. Fluid Leakage: Probably the most prevalent points is fluid leakage. This can happen because of worn seals, broken hoses, or defective connections. • Whereas working hydraulic hammers, by no means depart it in the same spot for a protracted time period. By doing so, you'd create an extreme amount of heat that may lead to instrument breakage. • Do not use a hydraulic breaker underwater as a result of should you do, it is going to contaminate the hydraulic system. Using hydraulic hammers underwater is feasible, but only should you hooked up their air compressor package exactly as instructed.

Our unbelievable availability and elements which are in-inventory and ready to ship quick minimize your downtime and get you again to work as quickly as potential. Our parts specialists are extremely trained and knowledgeable on all Volvo Heavy Gear machines, with exclusive entry to the manufacturers’ components books, ensuring we identify the proper part in your specific EC210 mannequin. Plus, we supply some parts that dealers merely do not present. Searching for Volvo EC210 Excavator Elements? To ensure prompt and effective resolution of hydraulic issues in Bobcat Excavators, it is very important have a superb grasp of what restore options could be utilized. To deal with typical hydraulic dilemmas normally requires particular repairs or replacements that will utterly heal the system. Usually, worn-out or damaged hoses end in leakage cases and inefficient systems. Discovering out which hose is faulty. Releasing the stress within the system earlier than removing hose. Fitting the new hose, making certain right routing and securing against put on or injury. Seals, fittings and even cracks on components could cause leaks of the fluid from hydraulics. Altering gaskets and seals that have worn out. In extreme instances equivalent to where broken parts are inflicting leakage, welding by professionals could be a solution or alternative necessitated as an alternative.

- 이전글The Loss of life Of High Stakes Download Link Http Dl Highstakesweeps Com And Learn how to Avoid It 24.10.18

- 다음글US State Department's top China policy official to step down 24.10.18

댓글목록

등록된 댓글이 없습니다.